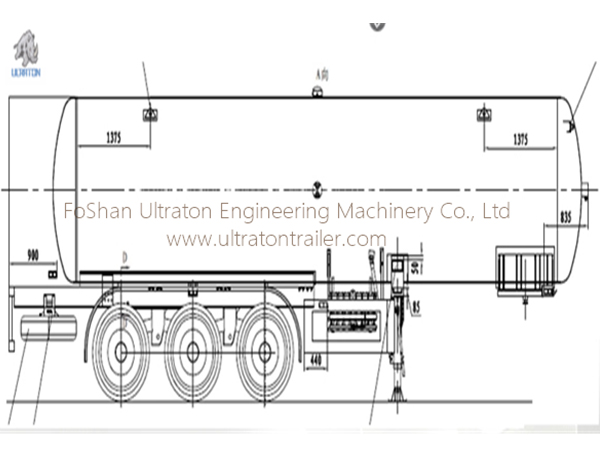

20m³ Semi Tanker Trailer

Ultraton 20m³ Tank Semi Trailer is a properly designed model ideal to transport fuel. It can be modified according to customer's requirement.

- Overview

- Advantage

- Application

- Other notes

Overview of 20m³ Semi Tanker Trailer

Heavy duty and extra durability designed for chassis frame and main beam.

Thickness of top plate, side plate and bottom plate of tank barrel could be customized

Steel material we use on barrel, bulkhead and baffle is carbon steel Q235B

Welded by automatic submerged-arc process and skilled technicians. Complete chassis shot blasting to clean rust.

Optional for one or more compartments

All tank fittings are strictly selected domestic famous brand for filling and unloading system and safety protection system

Superior quality and famous brand we use on specific different trailer parts. Details are outlined as below

Advantage of 20m³ Semi Tanker Trailer

Different shape and material of tank is optional for solution

Shipped both by container, or RORO, bulk shipment.

Nice and attractive appearance with our good workmanship

Fast response and flexible service from our professional team

Distinct location to get full range support on delivery and manufacturing

Ultraton's long term tenet to be your reliable partner bringing you Greater value makes you worry free on after sales service

| Technical Parameter | 20m³Tanker Semi Trailer |

| TANK BARREL | |

| Tank Profile | Elliptical, Straight, Maximum profile design that maximizes volumetric capacity whilst achieving a low centre of gravity. |

| Design Code/Testing | According to china standard,refer to ADR Standard. Hydrostatic test to 5 psi (35 Kpa) on each compartment |

| Capacity | 20000L plus maximum 5% Ullage. |

| Main Beam | Carbon stee Extrusion , full-length main frame. |

| Roll Over Coaming | Carbon steel Extrusion in inverted “U” section, for roll over protection. At least 30mm above any fittings on the top of the barrel, 3/8” degassing plug at the front-top & rear-bottom. |

| FITTINGS AND PIPING | |

| Manhole Cover | Domestic manhole cover, with relief valve(top inlet for oil), Pressure Vacuum Vent, overfill hole and vapour transfer vent hole ( *5) |

| Pressure Vacuum Vent | Domestic, roll-over type incorporates with manhole cover (*5) |

| Vapour Vent | Domestic, sequential pneumatic control air vent (*5) |

| Vapour Recovery Hose | 3” hose, connected with vepour vent to the left side coaming rail, Stainless steel hose clips as need. |

| Vapour Recovery Piping | 4” Carbon steel pipe from rear right side roll over coaming to rear of the barrel, outside of the barrel, connected with vapour recovery adaptor. |

| Vapour Recovery Adaptor | Domestic with pneumatic vapour interlock valve and dust cap, install at rear right side of the barrel. (*1) |

| Vapour Dump Vent | Domestic, air operated, dump vent close when the vapour adaptor is activated, installed at the rear right inner side of roll over coaming, vented to atmosphere. (*1) |

| Emergency Valve | pneumatic controlled emergency valve at all compartments, flange coupling to discharge pipe (*5) |

| Discharge Piping | 4” Carbon steel discharge pipe to the right side of trailer with minimum number of bends. Piping to be hydro-statically tested. The piping slope toward front at angle of 2-3 degrees. |

| Loading & Discharge Valve | DN 80 du type FIDLOCK aptor c/w flange type sight glass & dust cap on the right side at centre of tanker. The offset distance from centre to centre of API is 300mm. (*5) |

| Overfill Prevention | Civacon 5 wire optic probe installed to manhole cover, 1 piece Civacon 10 pin, 3J slot plug socket installed above the discharge control cabinet. (*5) Probe need to be set at minimum 25mm above top full ullage marker in each compartment. |

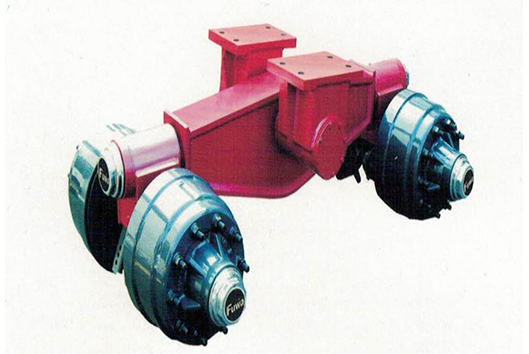

| RUNNING GEAR | |

| Landing Gear | Standard 28Ton , FUWA Brand |

| Axle | Standard FUWA Brand / ULTRATON Brand Optional : BPW Brand or HuaJing Brand |

| Suspension | Mechanical Suspension/Air Suspension,Standard FUWA Brand/ULTRATON Brand Optional : BPW Brand or HuaJing Brand |

| Tire | 12.00R22.5 Tubeless |

| Rim | 9.0*22.5 |

| Shot Blasting & Painting | Shot Blasting and Sanding Treatment . Two Coat Of Anti Corrosion Primer and Two Coat Of Finish Painting |

| Tool Box | 1 Standard (The Tool Box Size Can Be Tailored To Suit Your Needs) |

| We Can Build The Trailer According To Customer’s Design And Requirement. | |

Application of 20m³ Semi Tanker Trailer

Ultraton's 20 m3 Semi Tanker Trailer could be used to transport different oils dispensed separately or in separate positions.

Leave us Message: